Cooling Tower Water Treatment

The thermal efficiency and longevity of any systems cooling tower and associated equipment depend on the proper management of its recirculated water. Operators Unlimited offers the experience and expertise to evaluate, automate and maintain the efficiency of these systems.

Do you know what’s going on in your water? As a service of Operators Unlimited, the chemistry of cooling tower water and the process of preventing corrosion, scaling and biological build up is at the forefront of cooling tower system management. Scaling and corrosion can be costly, not only to equipment, but in your water efficiency efforts. A well-designed chemical treatment system that maintains optimal chemical dosage is a great jumping off point.

Operators Unlimited provides lab studies to not only evaluate your water, but to understand your process needs and determine the optimal chemicals and their minimal dosage required for efficiency. We design chemical feed systems and provide the necessary equipment including pumps, chemical storage tanks and instrumentation.

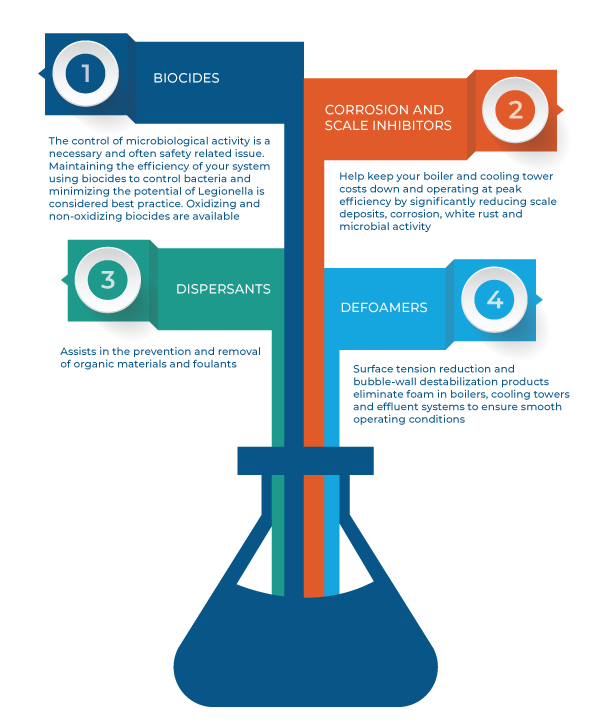

Most Common Chemicals Used for Cooling Tower Water Treatment

Maintaining an optimal balance of water to not only prevent corrosion by controlling mineral concentrations, but also to manage the blowdown/bleeding process can be a challenge. Cooling tower blowdown is the process of purging a portion of high mineral concentration cooling tower water down the drain and replacing it with fresh water. This process dilutes the system water mineral concentrations that regularly increase due to water evaporation. If this process is not performed the mineral content will fall out of the water and form scaling in the system.

Water costs for cooling tower systems can often account for the highest water usage in a plant. There is a huge potential for water savings and lowering operational costs by instituting a cooling tower water management plan.

Benefits of Managing Cooling Tower Water: Asset Protection, Energy Savings and Water Savings

Asset Protection

- Reduce Probability of failure

- Reduce Maintenance Costs

- Protect Asset Value

Energy and Water Savings

- Utilize a well-designed chemical treatment program to reduce build-up

- Maximize Cycles of Concentration

- Conduct Lab Studies to determine minimum effective chemical dosage

Chemical Treatment & Optimization

Cost-effective chemical supplier and custom designed blend resource, resulting in compliant effluent with safe impacts on your company and community.

Learn More

Operational Support & Staffing

Achieve predictable wastewater operational efficiency through, licensed operational staffing, technical support and project management. Need an operator of record, relief staff or full-time operators or a more full-service solution with OU managing your entire wastewater plant? Reach out to discuss our staffing options.

Learn More

Equipment

Operators Unlimited can supply all your wastewater equipment needs. From chemical feed systems to tanks and clarifiers, contact our technical sales team for a quote.

Learn More

Engineering Services

Controlling the cost of wastewater treatment while meeting regulatory obligations can be complicated. OU engineers specialize in identifying creative solutions for our clients’ wastewater challenges and utilize the most advanced technology to turn facility problems into cost saving operational solutions.