The old song Lean on Me reminds us that life is hard and that we all need other people to “Lean on.” The chorus says:

Lean on me, when you’re not strong

And I’ll be your friend

I’ll help you carry on

For it won’t be long

‘Til I’m gonna need

Somebody to lean on

(Lean on Me lyrics © Universal Music Publishing Group, BMG Rights Management, Royalty Network)

A little leaning on someone else in our lives is a good thing and a little “leaning” in wastewater clarification can be good for increasing settling performance. The physics that work in a lamella clarifier, also called an inclined or slant plate clarifier, can make a big difference in speeding up the settling rate of particles in wastewater. Let’s look at the science of settling in a non-science sounding kind of way. In wastewater there are particles that must be settled out of the water to make the water clean to be in conformity to a plant’s permit. If a particle in water is denser than the water, it will naturally settle to the bottom. But different factors determine how fast the particles will settle out. The speed of which a particle settles is called the settling velocity. Settling velocity can be calculated by using a scientific equation that depicts, STOKES’ LAW. The Stokes’ law equation uses several variables including the densities of the particle and fluid, viscosity of the liquid, gravitational pull on the particle, and size of the particle.

Stokes’ Law = v = 2/9(d1 – d2)gr2/η

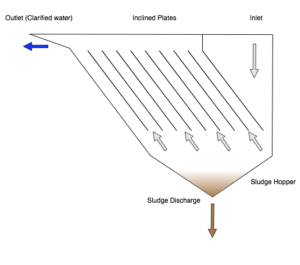

Not to get caught up in the weeds, but let’s summarize. Stokes’ law can explain why a Lamella Clarifier can clarify a larger amount of water than a traditional clarifier in less amount of time, while occupying less space. Gravity causes particles to naturally fall to the bottom over time. Falling particles in the water in a lamella clarifier travel a much shorter distance than they must in a traditional clarifier. This is because there are a series of angled plates inside of the lamella clarifier that are only a few inches apart (see diagram). This is important because the particles reach a solid surface much quicker with these inclined plates. And as the particles hit the angled plates they begin to gather and then this creates a cumulative effect of these particles moving down the solid surface together. They group up and gain momentum. An interesting part of thi s process is that, in a lamella clarifier, the water is forced upward through the inclined plates, yet the particles still settle and move in the opposite direction to the flow of the water. This again is due to the gravitational pull on the particles.

s process is that, in a lamella clarifier, the water is forced upward through the inclined plates, yet the particles still settle and move in the opposite direction to the flow of the water. This again is due to the gravitational pull on the particles.

This process allows for the processing of more water, in less time, and in a smaller space due to the plates creating more surface area for settling to occur. Thus, the faster the particles reach a solid surface the faster clarification occurs. The lamella clarifier process makes this kind of clarifier ideal for certain applications where space is limited or settling needs to occur indoors

In the pictures associated with this article, you can see a lamella clarifier in a plant where we are doing a complete managed wastewater program. Notice the leaning shape of the lamella clarifier and the small amount of floor space that the clarifier occupies. At this plant, this process is used in a metals precipitation application. You will often find a lamella clarifier used in metal finishing wastewater treatment, but sometime municipalities will use it as well. Other applications include Food Processing, Concrete, Surface Finishing, and others.

As in other clarification processes associated with pretreatment, chemistry is often used in conjunction with the clarifier. Adding a polymer, like our OU 100 coagulant, can be even more helpful in increasing the settling rate and effectiveness of the clarifier. (See our article: Polymers and their use in Wastewater Treatment). At your request we would be glad to visit your plant to survey your wastewater operation and then make recommendations that could help give you peace of mind and improve your operational efficiency. Contact us today to begin a conversation about your plant and your wastewater challenges. We have the experience and expertise to help with just about anything related to wastewater. Click here to contact us.